Engine :

It acts as the power unit. The internal combustion engine is the most commonly used in automobiles. It is of two types ;

(i) Spark ignition

(ii) Compression ignition.

Both engines are called heat engines. A steam engine is an external combustion engine because the fuel is burned outside the engine. The principle of working of an external combustion engine is shown in the figure below.

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber. In an internal combustion engine the expansion of the high temperature and pressure gases, which are produced by the combustion, directly applies force to a movable component of the engine, such as the pistons and by moving it over a distance, generate useful mechanical energy.

The internal combustion engine is quite different from external combustion engines, such as steam in which the energy is delivered to a working fluid not consisting of, mixed with or contaminated by combustion products. Working fluids can be air, hot water, pressurised water or even liquid sodium, heated in some kind of boiler.

BASIC ENGINE DESIGN

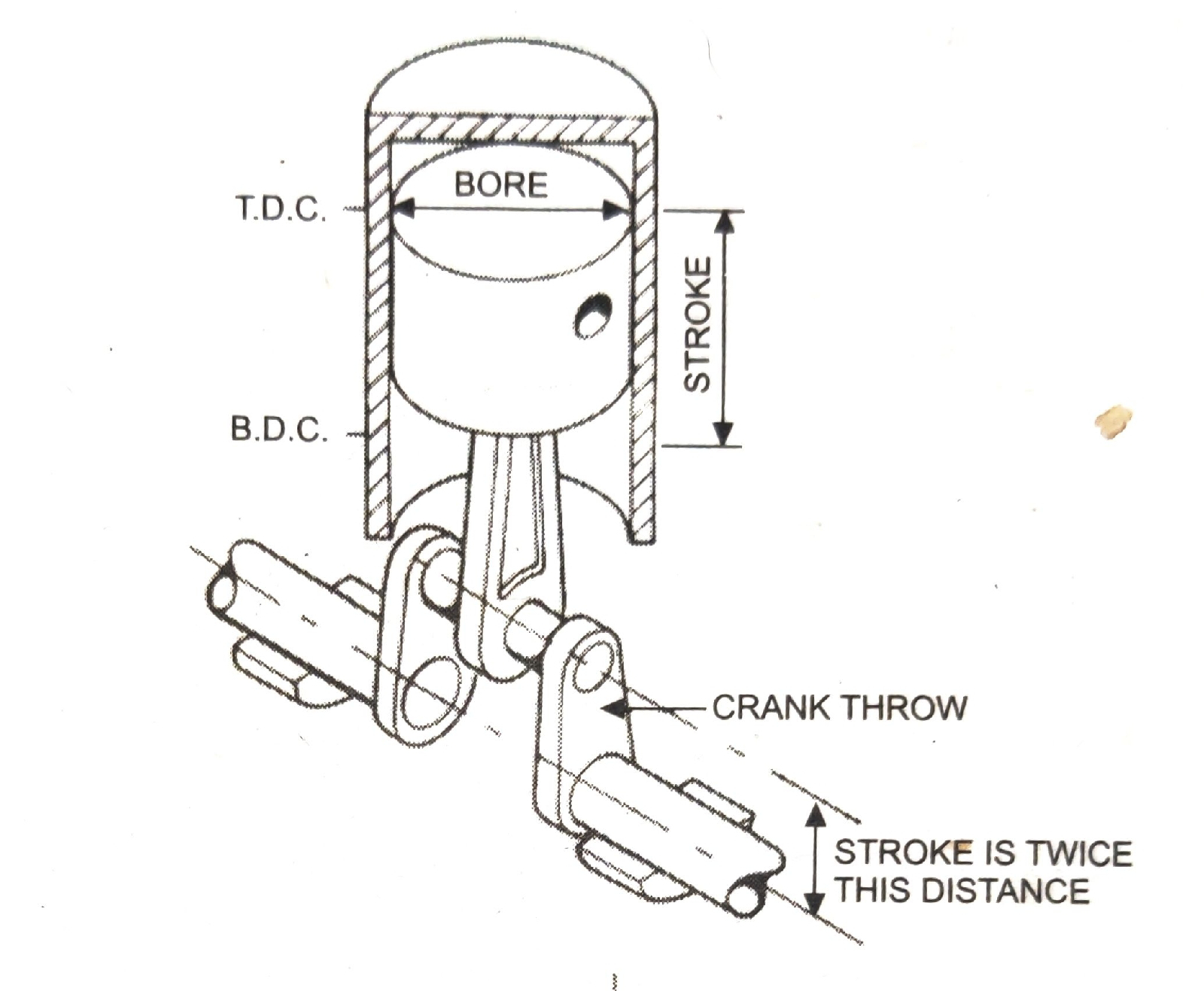

The basic petrol-engine design consists of a hollow metal cylinder, in which a close-fitting piston is free to move up and down. The piston is connected to a rod, which is pivoted where it joins the piston. At the other end of the rod, called the connecting rod, is a bearing that allows it to rotate on the crankshaft, which is itself free to rotate.

T.D.C. (top dead centre) — The position of the crank and piston when the piston is farther away from the crankshaft.

B.D.C. (bottom dead centre) — The position of the crank and piston when the piston is nearest to the crankshaft.

Stroke — The distance between B.D.C. and T.D.C.

The stroke is controlled by the crankshaft.

Lead — Opening of valves before the time is known as lead, as opening of inlet valve even before the T.D.C. and opening of exhaust valve even before B.D.C.

Lag — Closing of valve after the time is called lag, as the inlet valve remains open even after T.D.C. and in the same way exhaust valve remains open even after T.D.C.

Overlap of valve — In most engines, the inlet valve opens at the time when the exhaust valve also remains open in the exhaust stroke. In this way both the inlet and exhaust valves remain open for some time. This timing is called overlap of valve.

Bore — The internal diameter of the cylinder.

Swept volume - The volume between T.D.C. and B.D.C.

Engine capacity - For piston engines, an engine’s capacity is the engine displacement, in other words the volume swept by all the pistons of an engine in a single movement. It is generally measured in litres (L) for larger engines, and cubic centimetres for smaller engines.

Clearance volume - The volume of the space above the piston when it is at T.D.C.

Compression ratio = (Swept volume + Clearance volume) / Clearance volume

Brake horsepower (BHP): It is the power output of an engine at the flywheel.

BHP = 2π ΝΤ / 4500

where N is rpm of the crankshaft and T is the torque produced.

Indicated horsepower (IHP) : It is the power developed in the engine cylinder.

Frictional horsepower: It is the horsepower lost in the engine due to friction.

FHP = IHP – BHP

Mechanical efficiency : It is the ratio of the power delivered (BHP) and the power available in the engine (IHP). It is expressed in percentage.

Volumetric efficiency : It is the ratio of the volume of the mixture drawn in the cylinder during suction stroke and volume of the cylinder.

Throw : It is the distance between the centre of the crankpin to the centre of the main journal. The piston stroke is double the throw.